Shouguang this enterprise, orders skyrocketed!

In recent years, Shouguang, led by "new" and driven by "intelligence", has accelerated the cultivation of new quality productivity and promoted the development of enterprises in the direction of intelligence and innovation. Shouguang Feitian Electronics is a typical representative of them. Through independent research and development and technological upgrading, the enterprise has continuously improved its core competitiveness, and the order volume has reached a record high.

2025-06-13

What factors affect the piezoelectric properties of piezoelectric ceramic materials?

The factors affecting the piezoelectric properties of piezoelectric ceramic materials mainly include the characteristics of the material itself, the preparation process and the external environmental conditions, as follows: the main crystal phase of piezoelectric ceramics (such as lead zirconate titanate PZT, barium titanate BaTiO, etc.) directly determine the piezoelectric properties of the 1. material composition and crystal structure. For example, the adjustment of the zirconium-titanium ratio (Zr/Ti) in PZT will change the Curie temperature and piezoelectric coefficient. When Zr/Ti is close to 52/48, the material is in the quasi-homotypic phase boundary and the piezoelectric performance is the best. Doping elements (such as La, Nb, Sr, etc.) can be replaced by the crystal lattice.

2025-06-09

Application of Piezoelectric Ceramics in Precision Manufacturing and Semiconductor Industry

With its high-precision displacement control, high-frequency vibration response, and non-electromagnetic interference characteristics, piezoelectric ceramic series products have become key technical components in the precision manufacturing and semiconductor industries, and are widely used in nanoscale processing, wafer processing, packaging inspection and other scenarios. The following is a detailed analysis of its core application scenarios and technical advantages: 1. precision positioning and nano-scale processing 1. Piezoelectric nano-positioning platform application scenarios: lithography objective focusing, electron beam exposure system, atomic force microscope (AFM) scanning, micro-electro-mechanical system (MEMS) device assembly. Technical advantages: sub-nanometer precision: through the inverse piezoelectric effect to achieve electrical signals to the machine

2025-06-06

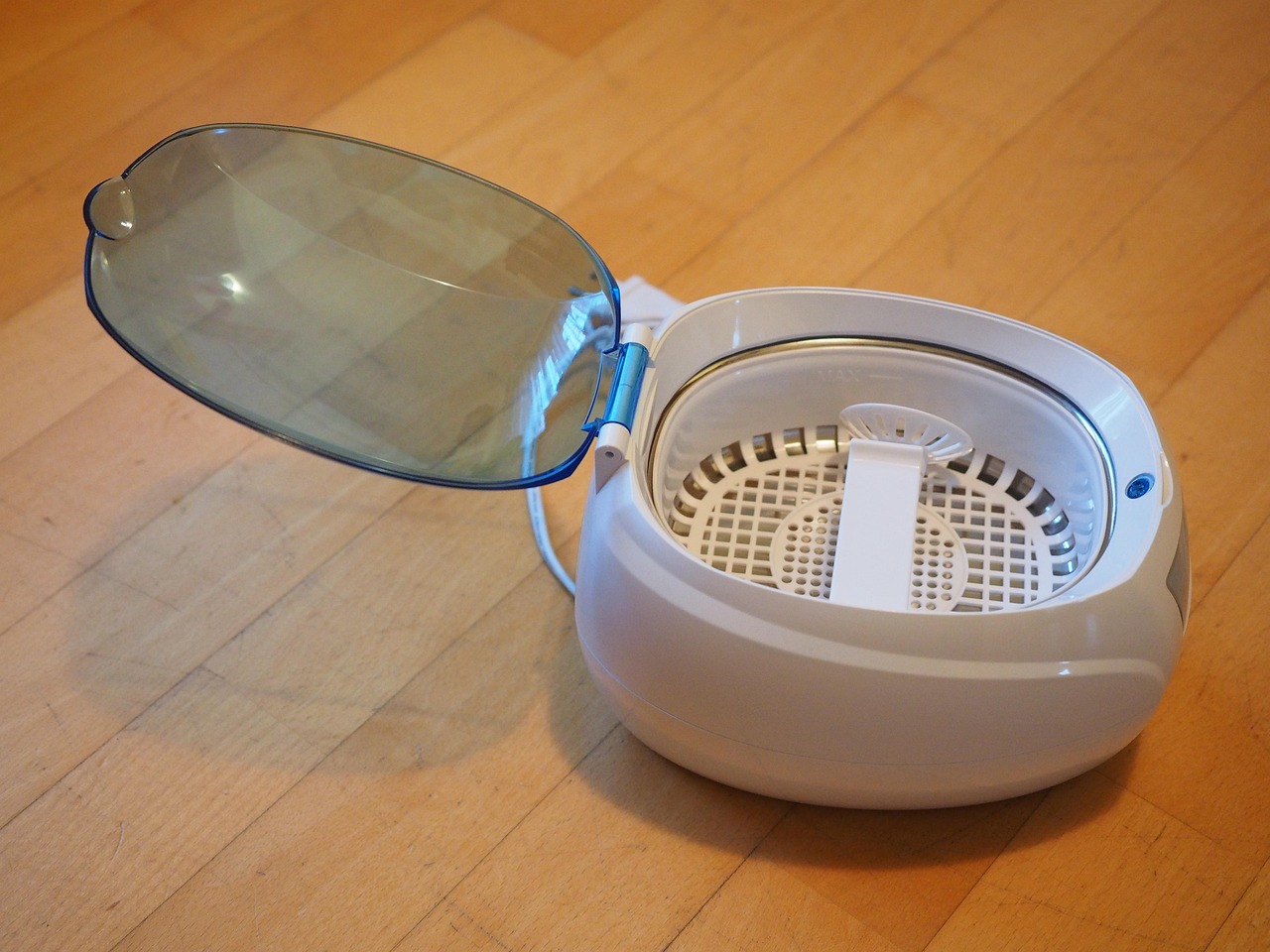

What are the advantages of piezoelectric ceramic series products in the application of ultrasonic cleaning?

The core characteristic of piezoelectric ceramics is the piezoelectric effect-high-frequency mechanical vibration is generated by electrical signal excitation, and electrical energy is efficiently converted into ultrasonic energy.

2025-06-05

What are the precautions when using piezoelectric ceramic series products?

When using piezoelectric ceramic series products (such as transducers, vibration components, etc.), it is necessary to operate carefully in combination with their physical characteristics and working environment to ensure safety, stability and service life. The following is a detailed description of the key considerations: 1. electrical connection and parameter control 1. Power supply matching and voltage stability must use a special driving power supply: piezoelectric ceramics should be matched with a matching high-frequency power supply (such as ultrasonic generator), and the power supply frequency should be consistent with the resonant frequency of ceramic components (the error usually needs to be <5%), otherwise it may lead to efficiency dips or component overheating damage. Avoid overvoltage/overcurrent: the voltage fluctuation range should be controlled

2025-06-04

What are the application scenarios of piezoelectric ceramic actuators?

Piezoelectric ceramic actuator is a device that uses the inverse piezoelectric effect of piezoelectric materials (that is, mechanical deformation occurs when an electric field is applied to piezoelectric materials) to achieve precision displacement output. It has the characteristics of fast response speed, high displacement accuracy, and compact structure. It is widely used in many fields. The following is a detailed introduction for you: Semiconductor manufacturing equipment in the field of precision machinery and manufacturing: in the lithography machine, it is used to control the nano-scale precision positioning of the lens and the wafer platform to ensure the high-precision etching of the chip pattern, and in the semiconductor packaging equipment, it is used to control the precision motion of the welding head of the wire bonding machine to improve the welding accuracy and reliability. Precision Machine Tools and Machining: As Machine Tools

2025-06-03

中文

中文 EN

EN